Liquid penetrant inspection

What is Liquid Penetrant Inspection?

Dye penetrant inspection (DPI), also called liquid penetrant inspection (LPI) or penetrant testing (PT), is a widely applied and low-cost inspection method used to locate surface-breaking defects in all non-porous materials (metals, plastics, or ceramics). The penetrant may be applied to all non-ferrous materials and ferrous materials, although for ferrous components magnetic-particle inspection is often used instead for its subsurface detection capability. LPI is used to detect casting, forging and welding surface defects such as hairline cracks, surface porosity, leaks in new products, and fatigue cracks on in-service components.

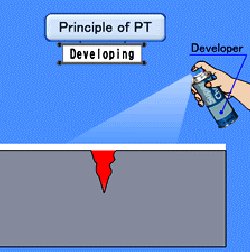

In Fluorescent Penetrant Inspection (FPI) or Liquid Penetrant Inspection (LPI) the surface of a part is saturated with a dye. The dye is cleaned off and a developer is applied to the part, drawing out any dye that has penetrated imperfections such as cracks, to reveal surface irregularities.

1. Section of material with a surface-breaking crack that is not visible to the naked eye.

2. Penetrant is applied to the surface.

3. Excess penetrant is removed.

4. Developer is applied, rendering the crack visible.

The inspector will use visible light with adequate intensity (100 foot-candles or 1100 lux is typical) for visible dye penetrant. Ultraviolet (UV-A) radiation of adequate intensity (1,000 micro-watts per centimeter squared is common), along with low ambient light levels (less than 2 foot-candles) for fluorescent penetrant examinations. Inspection of the test surface should take place after 10 to 30 minute development time, depends of product kind. This time delay allows the blotting action to occur. The inspector may observe the sample for indication formation when using visible dye. It is also good practice to observe indications as they form because the characteristics of the bleed out are a significant part of interpretation characterization of flaws.

Our skilled inspection technicians use ultraviolet and white-light inspection booths to examine and record defects.